Motivation

Latent heat storage represents an effective heat storage technology and utilizes the phase change solid/liquid of a so-called phase change material (PCM). When the storage unit is charged with heat, the PCM melts and solidifies again when discharged, so that a large amount of heat can be stored per unit volume at an almost constant (melting) temperature. The most precise possible knowledge of the thermophysical material and transport variables of these PCMs as storage media is an important prerequisite for the thermal design of these innovative heat storage systems. PCM manufacturers usually provide little data in this respect.

Objectives

Typical PCMs in latent heat storage systems are organic substances such as kerosenes, fatty acids and sugar alcohols or inorganic substances such as salt hydrates and salts. The density, specific heat capacity and thermal conductivity of the liquid and solid phases, the specific heat of fusion and the viscosity of the liquid phase are required for the reliable thermal design of latent heat storage systems. As part of the PCM-Prop 1 to 3 projects, the metrological equipment for determining these material and transport variables has been and is being procured or developed. This is then used to systematically examine PCM samples from various manufacturers and also other materials suitable as PCM (e.g. plastics). The measurement results are systematized and documented in the form of empirical equations or in database form.

Methods

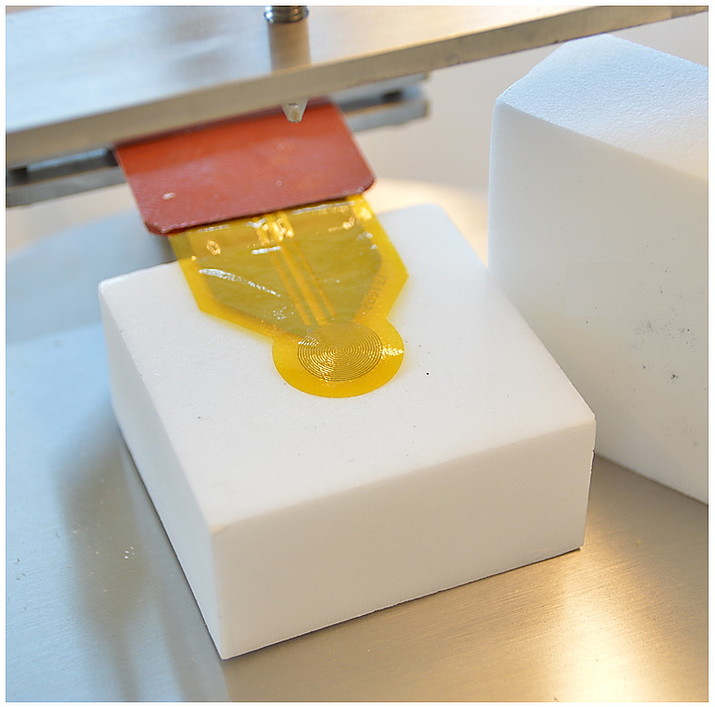

To measure the density of solid PCMs, geometrically defined samples are produced, their volume calculated and their mass determined using a precision measuring balance. The temperature-dependent density of the liquid phase can also be determined using the precision measuring balance, calibrated pipettes and the convection oven. The hot disk measuring system (top left) can be used to measure both the thermal conductivity (top center) and the specific heat capacity (top right, so-called cp measuring cell). The thermal conductivity is a substantial transport parameter for calculating the performance of a latent heat storage unit.

The specific heat of fusion and the specific heat capacity of the solid and liquid phase of the PCM can be determined with the aid of a so-called 3-layer calorimeter (bottom left) and the forced-air furnace (bottom center) - important material variables for determining the heat content of a latent heat storage unit. A quartz viscometer and a hot-wire measuring device (bottom right) are used to determine the viscosity and thermal conductivity of the liquid phase of the PCM. Knowledge of the density and viscosity of the liquid PCM allows an estimation of the influence of convection currents on the heat transport in the liquid phase of the PCM during loading of the latent heat storage, which should not be underestimated.

Results and outlook

The measurement technology mentioned above was procured and has already been used for numerous systematic investigations of a wide range of PCMs. In addition to our own research projects, metrologically determined material and transport variables of selected PCMs are already being used in commercial software for the design of complex energy technology systems. As a result of the PCM-Prop 1 to 3 projects, the Thermodynamics and Thermal Engineering Laboratory at the Zittau/Görlitz University of Applied Sciences has excellent and unique measuring equipment for determining thermophysical material and transport variables, not only of phase change materials. The next steps are to develop and implement appropriate measurement methods for PCMs in the high-temperature range.

none