Motivation

Heat storage systems are among the most important components for the successful implementation of the energy transition, especially the heating transition. Heat storage systems can bridge temporal and, in the case of mobile storage systems, also local discrepancies between heat supply and heat demand. Examples include the storage of waste heat, solar heat or heating or process heat generated from surplus green electricity (power-to-heat) as well as the storage of heat from electricity-operated combined heat and power plants for delayed use. When integrating a heat storage system into a thermal energy system, it is extremely important that the operating parameters of the storage system meet the requirements of the system in the best possible way. To select and dimension a suitable heat storage tank, the planner must be able to draw on generally valid comparative key figures. The project focuses on developing these.

Aims

The aim of the project is to define the most important operating parameters of thermal energy storage systems (heat and cold storage systems) as generally applicable comparative key figures. These include parameters such as the temperature range of the storage system, the achievable heat content under various boundary conditions, the performance of the storage system during charging and discharging, the auxiliary energy requirement, the losses occurring during storage and withdrawal as well as during the standby phase and the resulting efficiency parameters (e.g. efficiency levels). For reasons of practical relevance, the focus is initially on sensitive, hybrid and latent heat storage systems. With the help of the storage performance indicators, the planner should be able to select a suitable storage technology from the portfolio of different manufacturers for a specific application and optimally adapt the operating parameters of the selected storage system to the thermal energy system into which the storage system is integrated.

Methods

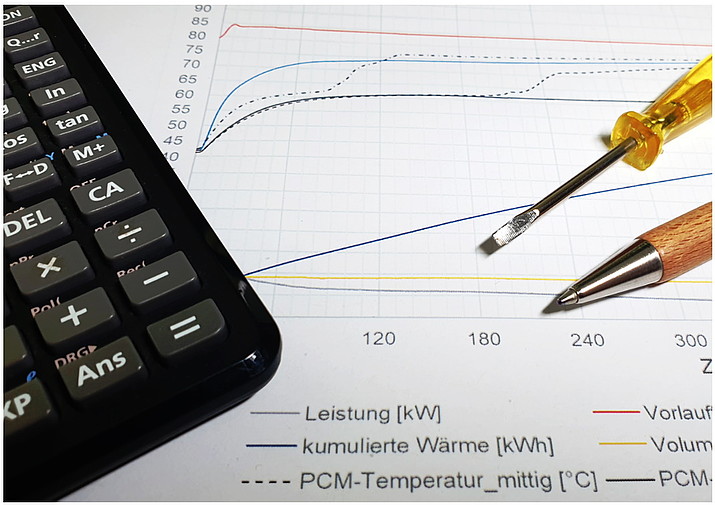

Initially, comparative key figures were developed by all project partners on the basis of the thermal engineering principles and summarized in a written document; this document will be continuously updated in the project. Key figures are defined for reference conditions (reference case), which the manufacturers of the thermal stores determine on prototypes on corresponding test benches. The planner can then use these key figures and convert them to the application conditions (use case). At the same time, the project partners set up or adapted test benches so that commercially available heat and cold storage tanks can be measured in accordance with the general specifications. At the Zittau/Görlitz University of Applied Sciences, tube bundle latent heat storage tanks, conventional hot water storage tanks and hybrid storage modules have so far been tested using the heat storage test facility in the Zittau power plant laboratory. The measurement results of all project partners are used to validate the manageability and accuracy of the developed key figures.

Results

The results of the project will be published in VDI 4657 Sheet 2 after its completion.