In the beginning of all technology was manufacturing. Man began to create tools at the very beginning of his development and use them to produce different things, i.e. to manufacture. Basic manufacturing processes are presented in our laboratory and their effects are made tangible.

Processes that are important in practice are tried out and demonstrated. These include casting, upsetting, deep drawing and the machining of metals by turning, milling and drilling. Practical results are compared with the theoretically calculated results based on the lecture knowledge and interpreted.

The laboratory is used by mechanical engineering and industrial engineering students in their undergraduate studies.

No internship can be successful without preparation. The students prepare for each experiment with the help of practical documents, which are provided in advance.

The practical course itself is supervised by the laboratory engineer and the specialist lecturer, who are also available to answer questions. Work is carried out in small groups of approx. 5 students so that everyone can get hands-on experience. The results and findings of the experiment are recorded in a protocol.

- Equipment for casting metals in sand mold casting

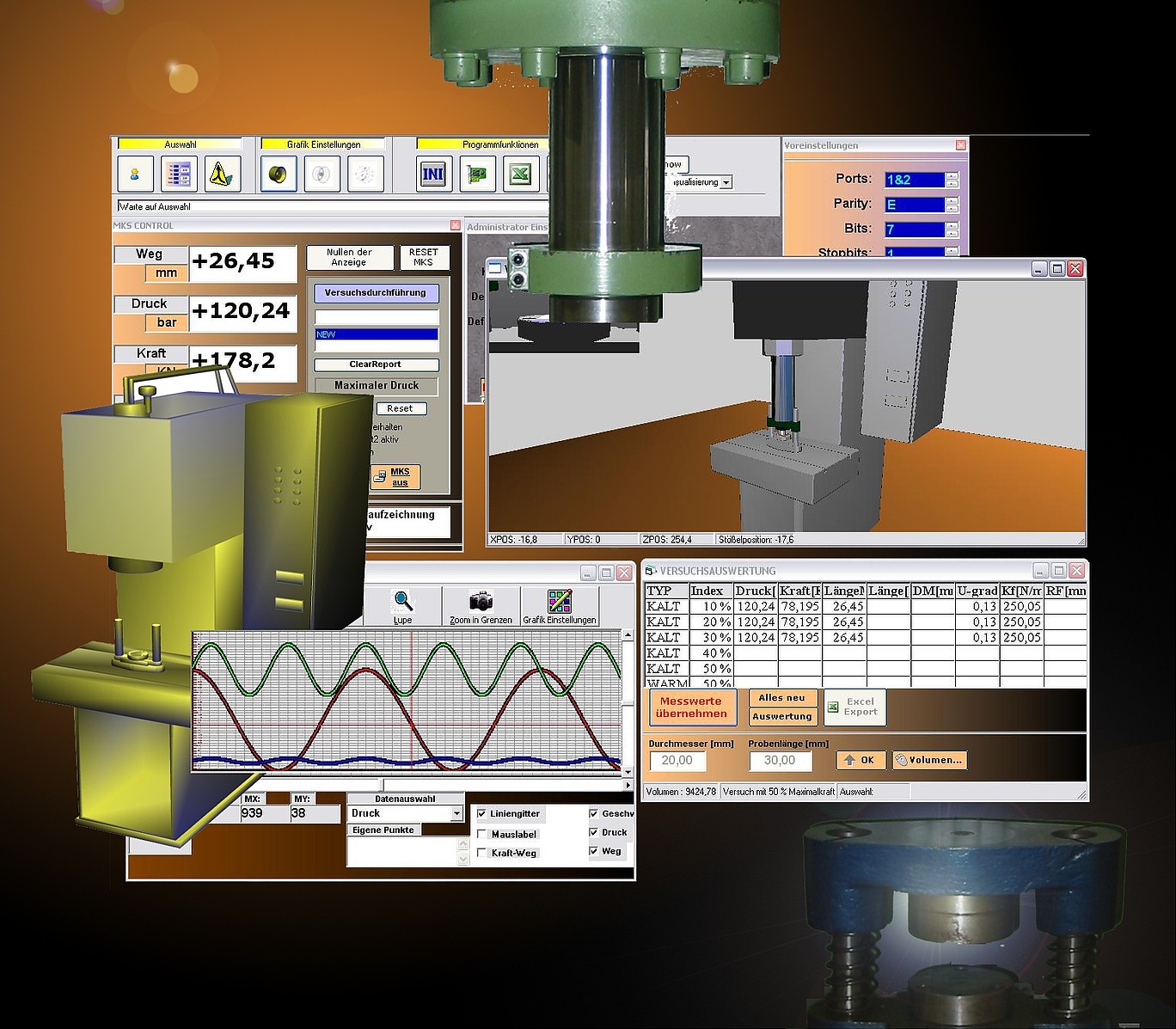

- Hydraulic press with upsetting and deep-drawing tools

- Lathe with cutting force measuring device

- Drilling and milling machine

Registration takes place by registering in small internship groups (5 to max. 10 students) via the e-learning platform OPAL.

House Z IVa, rooms 0.04 and 1.04.2