Motivation

Decentralized systems for heating or cooling, such as heating, air conditioning, solar or geothermal systems, use liquid media as a heat transfer medium, preferably water or water/glycol. Water is a good solvent for various gases and there is therefore a risk that these will outgas in the event of pressure or temperature changes and remain in the liquid as so-called free gases (gas bubbles). The ImpactGas project attempted to use experimental methods to answer the question of whether free or dissolved gases in heat transfer fluids lead to an impairment of the operating behavior of components and systems of the heating and cooling supply.

Methods

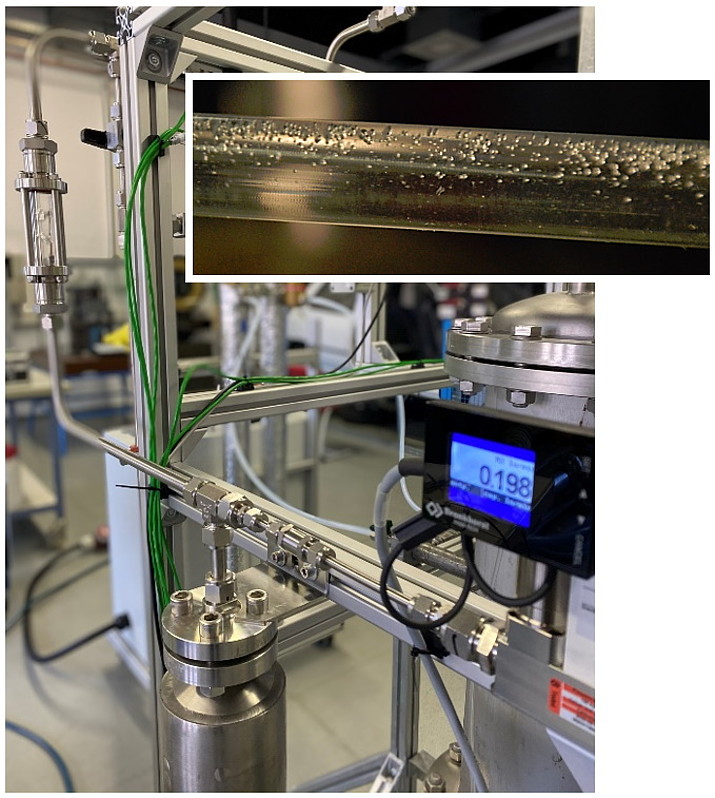

As part of the project, experimental investigations were carried out at the Zittau/Görlitz University of Applied Sciences into the flow and heat transfer in pipes as well as flow and thermal engineering components in the presence of a two-phase flow (liquid heat transfer medium with free gases). In close cooperation with the project partners, a complex test facility was developed to investigate the aforementioned phenomena and their implementation on a pilot plant scale. This system was used to carry out and evaluate detailed measurements on pressure loss and heat transfer in pipe flows (water liquid with N2 orCO2 as free gases). In addition, extensive component tests were carried out on finned tube and tube bundle heat exchangers as well as on an angle seat valve and a gear pump. The experimental investigations focused on the question of whether free gases accumulate in components and parts and lead to an impairment of the operating behavior.

Results

The most important parameter used to characterize the two-phase flow was the gas volume fraction or gas content, which quantifies the presence of free gases in the liquid in volume %. While in practice gas contents up to max. 5 % by volume are to be expected, the experimental investigations were carried out up to double the gas content. It was found that flow pressure losses in pipes and also through installations (e.g. an angle seat valve) increase in percentage terms approximately in the order of magnitude of the gas volume content with the corresponding effects, e.g. on the required drive power of circulating pumps. The investigation of the heat transfer proved to be difficult, but in the end improvements due to higher flow velocities and gas bubble-related turbulence effects were detectable.

Gear pumps deliver a constant volume flow at a constant speed, which contains less liquid due to the gas volume fraction, so that higher speeds are required in percentage terms in accordance with the gas volume fraction to ensure the supply task. The heat output of finned tube and shell and tube heat exchangers is only marginally affected by gas contents of up to 5% by volume; pressure loss increases are lower if the heat exchanger tubes run horizontally. Accumulations of free gases were not detected in the heat exchangers investigated.

All project work and results are summarized in the final report .